2025

Comparably’s Best Company Outlook

* Providing engineering services in these locations through SWCA Environmental Consulting & Engineering, Inc., an affiliate of SWCA.

From the experts we hire, to the clients we partner with, our greatest opportunity for success lies in our ability to bring the best team together for every project.

That’s why:

At SWCA, sustainability means balancing humanity’s social, economic, and environmental needs to provide a healthy planet for future generations.

SWCA employs smart, talented, problem-solvers dedicated to our purpose of preserving natural and cultural resources for tomorrow while enabling projects that benefit people today.

At SWCA, you’re not just an employee. You’re an owner. Everyone you work with has a stake in your success, so your hard work pays off – for the clients, for the company, and for your retirement goals.

Unpacking EPR Series: How Extended Producer Responsibility (EPR) Impacts the Plastic Packaging Circular Value Chain

In our Unpacking EPR series, so far, we’ve explored the fundamentals of extended producer responsibility (EPR) and why it matters for brand owners.

Tristan Steichen has more than 30 years of experience with global consumer product companies developing sustainability strategies, including the financial quantification of sustainability risks (including new legislation) and the business benefits of alternative solutions. Tristan’s technical expertise focuses on recycling and circular economy system implementation.

Tristan also serves as the Executive Director of the National Lubricant Container Recycling Coalition. Tristan has been leading the NLCRC since its inception in 2020. Initially focused on building a national recycling program for lubricant packaging, the NLCRC has expanded to include legislative advocacy, with a focus on Extended Producer Responsibility and other packaging-related legislation. Tristan is currently leading the NLCRC’s efforts to introduce a lubricant industry focused EPR bill in California.

Laura Nelson is an experienced leader and trusted advisor with over 18 years of experience in the environmental and sustainability services field. Laura has provided strategic sustainability services to clients in the food and beverage, consumer goods, manufacturing, technology, finance and energy industries. She has particular expertise in sustainability/ESG disclosure frameworks and standards, bolstered by a recent two-year position on the technical staff at the IFRS Foundation. Laura has also served as an Associate Director and facilitator for sustainability coalitions including the Beverage Industry Environmental Roundtable and the ISSB Technical Reference Group. As a Principal Sustainability Consultant, Laura provides clients with solutions that proactively address sustainability risks, recognize opportunities, build internal competency and governance of sustainability matters, and help navigate the complex sustainability disclosure landscape.

In our Unpacking EPR series, so far, we’ve explored the fundamentals of extended producer responsibility (EPR) and why it matters for brand owners. The first article introduced EPR packaging legislation and how states are implementing these laws, while the second article outlined who is responsible for compliance and the key deadlines producers need to meet.

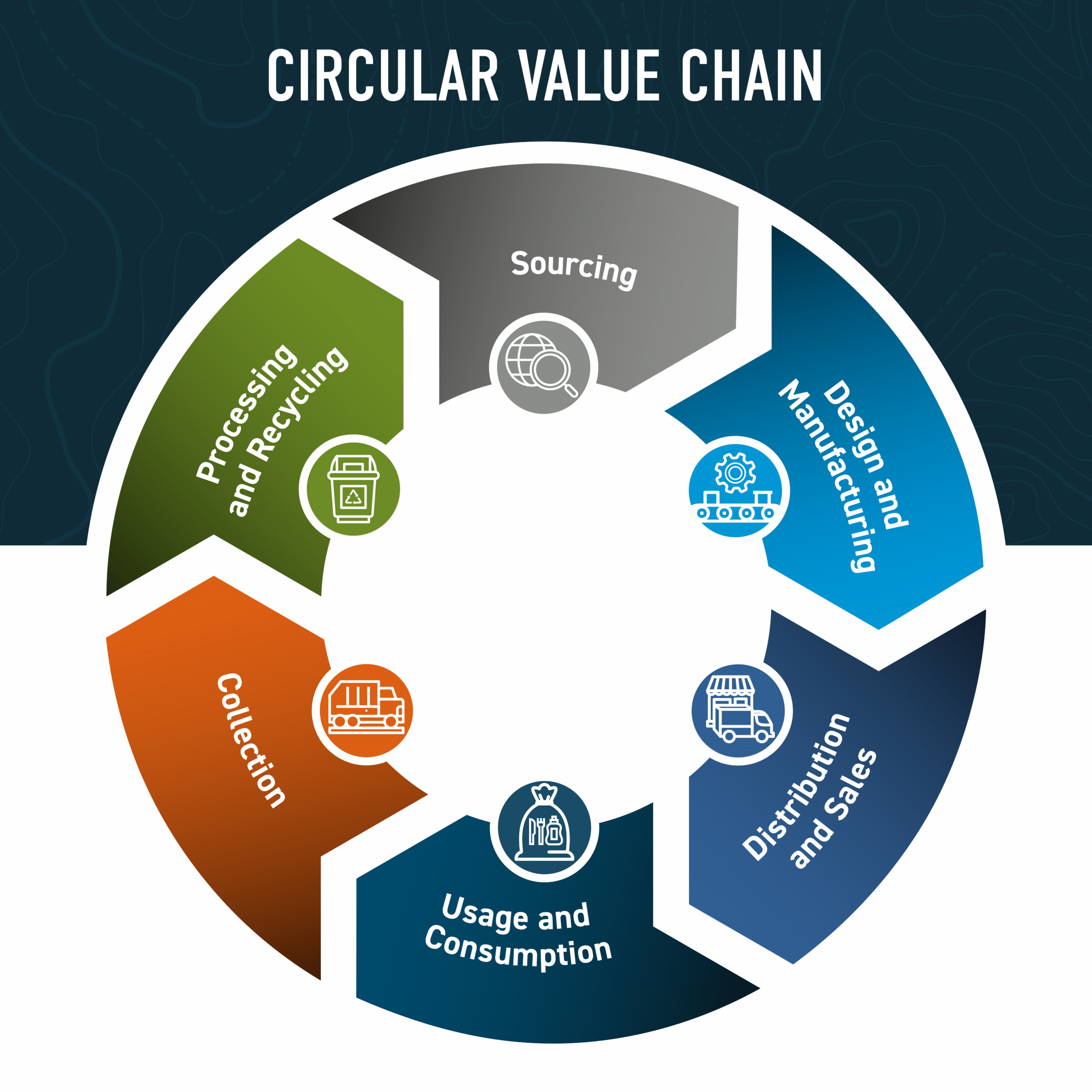

Now, we take a closer look at how EPR fits into the broader product circular value chain — the interconnected lifecycle stages of a product, from sourcing and manufacturing to recycling and reuse. Understanding this system is key to maximizing the benefits of EPR, reducing waste, and creating more sustainable business practices. We also examine the plastic packaging value chain to highlight the potential impacts and opportunities of EPR for various stakeholders.

Figure 1. Circular value chain lifecycle

The circular value chain for a product (or its packaging) involves a series of interconnected steps that illustrate its lifecycle, from sourcing and manufacturing to recycling and reuse (see Figure 1). Aligned with the principles of a circular economy, this system highlights key stakeholder dependencies needed to sustain the value of materials and products, thereby reducing waste and promoting sustainability. Here is a brief overview of the key stages:

Sourcing: Sourcing materials or chemicals necessary to make a product sustainably, by prioritizing recycled or renewable content, ensures a continuous flow in the market.

Design & Manufacturing: Design is one of the most critical components to circularity because it can consider concepts like post-consumer collectivity and recyclability of products. Examples include sourcing greater recycled content feedstocks, source reduction (or “lightweighting”), and other eco-friendly options. Manufacturers can optimize processes to minimize waste and energy consumption.

Distribution & Sales: Representing the interface between the manufacturer (or brand owner) and the consumer, communications about the benefits of circular products becomes critical, particularly for retailers who offer a broad range of products.

Usage & Consumption: For products, the objective is to design for ease of maintenance to extend the product’s lifespan and encourage long-term, proper use. For packaging, it is to educate consumers on proper disposal to optimize collection and recycling.

Collection: At the end of the product’s life, systems are in place to collect used products and packaging. This can involve take-back programs, recycling centers, or partnerships with third-party organizations.

Processing & Recycling: Collected products are sorted and processed to recover materials. These materials are then reused in the production of new products via recycling or other product-recovery solutions. The industry can reintegrate recovered materials into the sourcing process, reducing the need for virgin materials and minimizing waste, thereby closing the loop and creating a circular system.

A well-managed EPR program can potentially improve the circularity of a product, category, or packaging. Evaluating the plastic packaging value chain specifically, we explored the potential impacts and opportunities of implementing EPR on each segment of the value chain (see Figure 2).

EPR packaging laws are a mechanism that transfers financial accountability to producers for the recovery and recycling of products; however, the impacts of EPR are not limited to the producers themselves. For other stakeholders in the plastic packaging value chain, there will likely be indirect business impacts. Regardless of its role or position in the value chain, a company that proactively engages with customers and suppliers will be better positioned when EPR packaging programs launch and operate.

Although several states have passed EPR packaging laws, they are still in the policymaking stage and program implementation has yet to begin. There is still time for companies to prepare. Start by educating customers and suppliers on what EPR is, and then collaborating on developing solutions (e.g., product or packaging design improvements, alternative business models) that can lower risks (costs) of EPR implementation and potentially create new business opportunities.

As EPR packaging legislation continues to gain momentum, understanding and preparing for these changes is essential for producers and other members of the value chain. Our sustainability and management consulting experts at SWCA are at the forefront of EPR, circularity for consumer goods, and emerging sustainability compliance obligations. We’ve been leading the National Lubricant Container Recycling Coalition to accelerate the achievement of packaging recycling solutions for petroleum-based and related products in an industry that previously had no system for packaging recycling. SWCA is ready to help you navigate the compliance process, make the business case for your sustainability efforts, facilitate collective action, and drive the circular economy.

We invite you to stay tuned to our Unpacking EPR article series as we share more insights on EPR packaging laws and how producers can prepare for compliance.